Corporate Social Responsibility Report

Release time:

2024-06-13 15:51

1. Company Profile

Shandong Huacheng Zhongde Transmission Equipment Co., Ltd. is affiliated with Shandong Huacheng Group. Established in March 2010, it is located at No. 126, Zhangbo Road, Boshan District, Zibo City. It is a high-tech enterprise, a national specialized and new "Little Giant" enterprise, a Shandong Province manufacturing single champion demonstration enterprise, and a gazelle enterprise in Shandong Province. It has a Mechanical Industry Engineering Research Center, Shandong Enterprise Technology Center, and Shandong Industrial Design Center. It serves as the chairman unit of the Reducer Branch of the China General Machinery Industry Association. As a leading domestic gear transmission equipment R&D and manufacturing company, it focuses on high-end equipment manufacturing, dedicated to the R&D and production of high-precision gear transmission equipment. The company's main products include modular precision reducers, high-power heavy-duty gearboxes, geared motors, wind power gearboxes, and high-end gearbox replacement and remanufacturing.

The company strengthens quality management, environmental protection management, safety production management, and occupational health management through system certification work. It has passed certifications for quality management system, environmental management system, occupational health and safety management system, IQNET certification, and intellectual property management certification.

Precision reducers have passed certifications such as MAN certification, coal mine equipment maintenance service certification, and coal safety certification.

2. Corporate Social Responsibility

1. Corporate Safety Management

The company attaches great importance to safety management, establishing a safety management team led by the main person in charge (general manager) who assumes primary responsibility. The company has established a comprehensive three-level safety management system, clarifying responsibilities, tasks, and performance assessments at each level according to GB/T45001-2020/ISO45001:2018 occupational health and safety management system requirements. The company adheres to the principle of prevention first, formulating emergency plans for electricity, fire, flood, and sudden accidents to ensure systems, personnel, and organization are all in place. It regularly participates in safety education and training organized by municipal and district emergency and fire management departments and obtains certificates. It actively promotes safety production and holds emergency drills irregularly. Safety is prioritized in monthly and weekly leadership meetings where tasks are assigned. In recent years, no serious injuries or above accidents have occurred.

The company has passed occupational health and safety management system and dual prevention system certifications, emphasizing safety production and accident prevention. It adheres to a people-oriented philosophy, regarding employees as the company's most valuable asset; complies with laws and regulations to avoid operational risks; continuously strengthens the occupational health and safety awareness of all employees, improves employee health levels, ensures occupational health and safety during product realization processes, and provides employees with a safe, healthy, and comfortable working environment.

2. Environmental Protection

The company actively implements the development concept that "lucid waters and lush mountains are invaluable assets," placing environmental protection in a prominent position. According to GB/T 24001-2016/ISO14001:2015 environmental management system requirements, it identifies environmental factors, determines key environmental factors, sets targets and management plans for environmental improvement, and ensures compliance through conformity assessments. Environmental impact assessments are conducted for new projects and technological transformation projects. The company focuses on plant environment construction by planting trees and flowers, greening the environment, and creating a garden-style factory. Waste materials are centrally handled by qualified units according to environmental protection procedures to comprehensively reduce adverse impacts on the surrounding environment.

The company has passed environmental management system certification, emphasizing energy-saving, efficiency improvement, and integrated management. It saves energy and resources; controls pollutant emissions; reduces energy consumption; uses resources and energy reasonably; prevents or reduces environmental pollution; manages energy saving and emission reduction; improves energy utilization efficiency; reduces costs and increases efficiency; and promotes sustainable development of the enterprise.

3. Resource Conservation

In cooperation with the Zibo Municipal Government's Green Power Enhancement Project and the construction of a resource-saving society, the company has formulated the "Energy Saving Management System". According to ISO 50001:2011 energy management system certification requirements, it determines reasonable energy use and improves resource management levels, integrating energy-saving work throughout the production process. It has established advanced and reasonable energy consumption quotas and assessment methods and implemented clean production management.

The company consciously complies with energy-saving laws, regulations, and standards. By implementing the energy management system internally, it strictly follows the procedural documents of the energy management system to scientifically manage the work of each department. It continuously adopts new processes, technologies, and equipment to technically improve or replace high-energy-consuming process equipment, continuously improving energy management to achieve energy saving and emission reduction, comprehensive resource utilization, cost reduction, and increased benefits, jointly creating a green and low-carbon enterprise.

Through energy certification, the company promotes the R&D of clean and low-carbon product processes, enhancing competitiveness and establishing a good social image. It has gained recognition in energy management. In 2021, the company was recognized by the Zibo Municipal Bureau of Industry and Information Technology as one of the first batch of "Green Factories" in Zibo City.

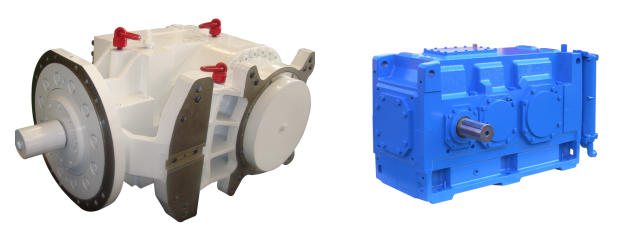

KPL Series Scraper Reducer H Series Modular Precision Reducer

4. Public Welfare Support

The company does not forget its social responsibilities during development. It actively participates annually in the "One Day Charity Donation" event, invests in multimedia teaching equipment for local schools, donates multiple times to students in financial difficulty, responds to government rural revitalization calls, and actively supports new rural construction and poverty alleviation through donations and contracting poverty alleviation projects. It supports the implementation of poverty alleviation projects in Shanzhuang Village, Yucheng Town. In special situations such as natural disasters, aid for the vulnerable, assistance for the disabled, etc., the company provides appropriate donations based on specific circumstances. The company’s party committee and labor union regularly organize visits to employees and party members in difficulty every year.

The company actively overcomes the impact of the COVID-19 pandemic, ensures work and production stability, maintains employment, and donated 50,000 yuan to the Boshan District Charity Federation for charitable development.

Related News